The selection of suitable gloves does not only depend on the material, but also on further marks of quality which vary from manufacturer to manufacturer.

Where the chemical is a preparation of several substances, the resistance of the glove material can not be calculated in advance and has therefore to be

checked prior to the application.

The exact break through time for substances has to be obtained from the manufacturer of the protective gloves and has to be observed when making a final

choice.

Personal hygiene is a key element of effective hand care.

Body protection

See Other protection below

Other protection

Overalls.

P.V.C. apron.

Barrier cream.

Thermal hazards

Not Available

Recommended material(s)

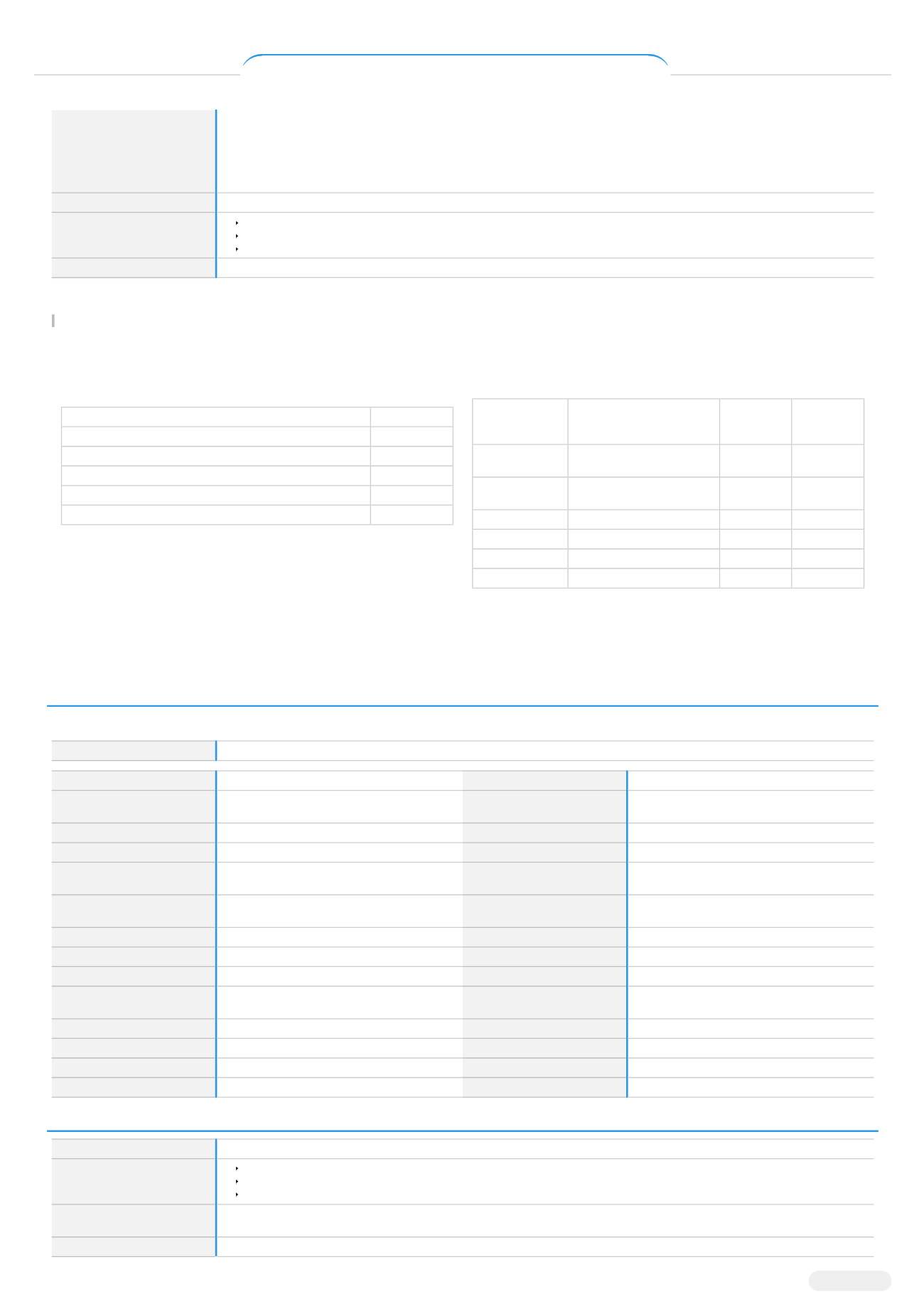

GLOVE SELECTION INDEX

Glove selection is based on a modified presentation of the:

"

Forsberg Clothing Performance Index".

The effect(s) of the following substance(s) are taken into account in the

computer-

generated

selection:

NV Chemicals Sugar Soap Liquid

Material

CPI

BUTYL

C

NATURAL RUBBER

C

NEOPRENE

C

PVA

C

VITON

C

* CPI - Chemwatch Performance Index

A: Best Selection

B: Satisfactory; may degrade after 4 hours continuous immersion

C: Poor to Dangerous Choice for other than short term immersion

NOTE

: As a series of factors will influence the actual performance of the glove, a final

selection must be based on detailed observation. -

* Where the glove is to be used on a short term, casual or infrequent basis, factors such as

"feel" or convenience (e.g. disposability), may dictate a choice of gloves which might otherwise

be unsuitable following long-term or frequent use. A qualified practitioner should be consulted.

Respiratory protection

Type AK-P Filter of sufficient capacity. (AS/NZS 1716 & 1715, EN 143:2000 & 149:2001, ANSI

Z88 or national equivalent)

Selection of the Class and Type of respirator will depend upon the level of breathing zone

contaminant and the chemical nature of the contaminant. Protection Factors (defined as the

ratio of contaminant outside and inside the mask) may also be important.

Required

minimum

protection factor

Maximum gas/vapour

concentration present in air

p.p.m. (by volume)

Half-face

Respirator

Full-Face

Respirator

up to 10

1000

AK-AUS /

Class1 P2

-

up to 50

1000

-

AK-AUS /

Class 1 P2

up to 50

5000

Airline *

-

up to 100

5000

-

AK-2 P2

up to 100

10000

-

AK-3 P2

100+

Airline**

* - Continuous Flow ** - Continuous-flow or positive pressure demand

A(All classes) = Organic vapours, B AUS or B1 = Acid gasses, B2 = Acid gas or hydrogen

cyanide(HCN), B3 = Acid gas or hydrogen cyanide(HCN), E = Sulfur dioxide(SO2), G =

Agricultural chemicals, K = Ammonia(NH3), Hg = Mercury, NO = Oxides of nitrogen, MB =

Methyl bromide, AX = Low boiling point organic compounds(below 65 degC)

SECTION 9 PHYSICAL AND CHEMICAL PROPERTIES

Information on basic physical and chemical properties

Appearance

Blue viscous alkaline liquid; mixes with water to form foaming solutions.

Physical state

Liquid

Relative density (Water = 1)

Not Available

Odour

Not Available

Partition coefficient n-octanol /

water

Not Available

Odour threshold

Not Available

Auto-ignition temperature (°C)

Not Available

pH (as supplied)

8-9

Decomposition temperature

Not Available

Melting point / freezing point

(°C)

Not Available

Viscosity (cSt)

Not Available

Initial boiling point and boiling

range (°C)

Not Available

Molecular weight (g/mol)

Not Applicable

Flash point (°C)

Not Applicable

Taste

Not Available

Evaporation rate

Not Available

Explosive properties

Not Available

Flammability

Not Applicable

Oxidising properties

Not Available

Upper Explosive Limit (%)

Not Applicable

Surface Tension (dyn/cm or

mN/m)

Not Available

Lower Explosive Limit (%)

Not Applicable

Volatile Component (%vol)

Not Available

Vapour pressure (kPa)

Not Available

Gas group

Not Available

Solubility in water (g/L)

Miscible

pH as a solution (1%)

Not Available

Vapour density (Air = 1)

Not Available

VOC g/L

Not Available

SECTION 10 STABILITY AND REACTIVITY

Reactivity

See section 7

Chemical stability

Unstable in the presence of incompatible materials.

Product is considered stable.

Hazardous polymerisation will not occur.

Possibility of hazardous

reactions

See section 7

Conditions to avoid

See section 7

Chemwatch:

4789-88

Version No:

3.1.1.1

Page

4

of

8

NV Chemicals Sugar Soap Liquid

Issue Date:

26/01/2018

Print Date:

31/01/2018

Continued...